Sponsor:

Air Force Office of Scientific Research (AFOSR), under the Department of Defense (DOD), under award number FA9550-12-1-0458; and National Institute of Standards and Technology (NIST), under Award No. 70NANB14H012.

Project Team Members:

Northwestern University

University of Michigan-Ann Arbor

Georgia Institute of Technology

Predictive Modeling in Materials Science

Overview

Predictive modeling could easily be the strongest suit of machine learning and data mining. A predictive system is often trained in a supervised fashion. It takes in a collection of samples in the form of input-output pairs, and once the system parameters are learned, it can be used to derive outputs for unseen inputs. Supervised learning can be very effective, because the loss of learning is well defined: the difference between predicted outputs and given outputs in training data.

Building a prediction system has become a mundane practice now, given there are out there many well written software packages, with which, building a data model is only couple of lines of codes away. Certainly we can study tricks of training, data pre-processing, and post-processing such as ensemble techniques to improve off-the-shelf systems. But what further pursuits are there?

Localization Problem

Localization describes the spatial distribution of the response at the microscale for an imposed loading condition (e.g., averaged strain) at macroscale. Localization is critically important in correlating various failure-related macroscale properties of the material with the specific local microstructure conformations responsible for the (local) damage initiation in the material.

Context Aware Predictive Modeling

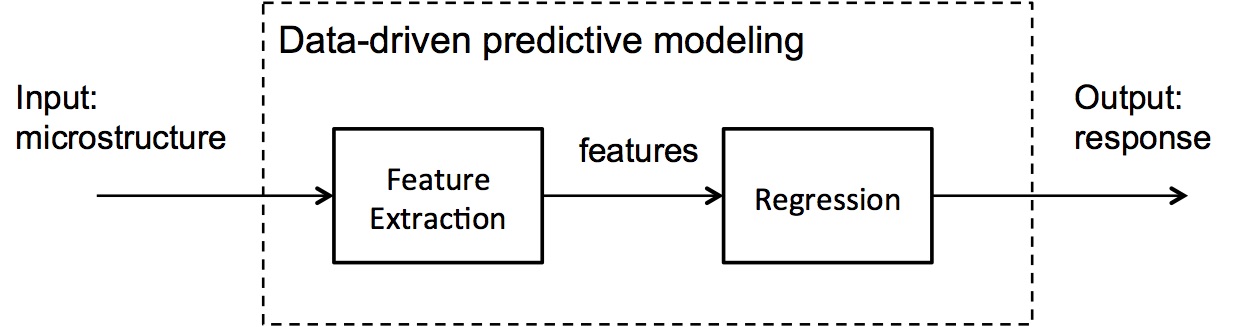

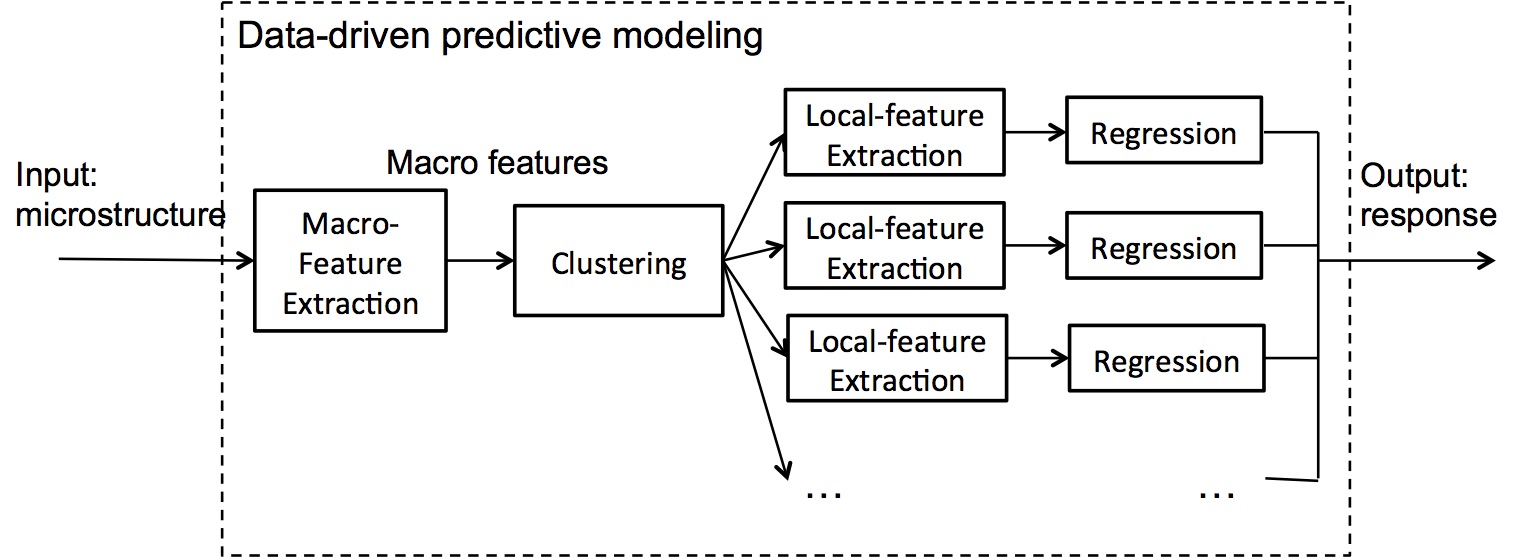

In one of our attemtps (see [1]), a regular data modeling system looks like this:

And such a system is entirely unaware of the hidden distribution of data that it's trained from. To make it better, we propose context-aware systems. Such a system calls for first detecting context groups, groups that are of high intra-similarity and low inter-similarity.

Homogenization Problem

Homogenization in hierarchical multiscale modeling refers to transfer of information about the microstructure from a lower length scale to higher length scale. This information is usually expressed as an effective property of the material volume being studied and is calculated through various averaging techniques.

Deep Learning Systems

As we are writing for this page, the area of deep learning have been advancing with prime interests from many fields. Deep learning refers to the class of methods that are capable of learning hierarchy of features from raw inputs, through deep neural networks. The flexibility of structure and the often huge number of parameters (tens to hundres of millions) make those networks powerful for capturing highly nonlinear mappings between inputs and outputs. Their capability of utilizing large data has demonstrated great success with various data types like image, speech, video, text and more.

Software Download

- Our theano based deep learning software package, deuNet, can be downloaded here. It is a general package that makes exploring different neural network architectures, training schemes, hyperparameters easy.

- The developed deep learning model of publications [3], MES Predictor, can be downloaded here. It can be directly used to predict macroscale (effective) stiffness of high-contrast two-phase three-dimensional composite materials.

Publications

- [1] Ruoqian Liu, Yuksel Yabansu, Ankit Agrawal, Surya Kalidindi, and Alok Choudhary. Machine learning approaches for elastic localization linkages in high-contrast composite materials. Integrating Materials and Manufacturing Innovation, 4(1):1–17, 2015. (pdf)

- [2] Ruoqian Liu, Yuksel Yabansu, Zijiang Yang, Alok Choudhary, Surya Kalidindi and Ankit Agrawal. Context Aware Machine Learning Approaches for Modeling Elastic Localization in Three-Dimensional Composite Microstructures. Integrating Materials and Manufacturing Innovation, (2017): 1-12. (pdf)

- [3] Zijiang Yang, Yuksel Yabansu, Reda Al-Bahrani, Wei-keng Liao, Alok Choudhary, Surya Kalidindi, Ankit Agrawal. Deep learning approaches for mining structure-property linkages in high contrast composites from simulation datasets. under review, 2017.

Acknowledgements

This work is supported by AFOSR (Air Force Office of Scientific Research), Department of Defense (DOD) under Award No. FA9550-12-1-0458; and by National Institute of Standards and Technology (NIST), under Award No. 70NANB14H012.